- Four of the company's five furnaces at full load, taking advantage of the profitable demand opportunity offered by the market.

- The renovation of furnace 12 at cee is part of the €28M plan committed to developing its 4 strategic axes: safety, environment, asset care, efficiency and productivity.

- In the ferroalloys division, XEAL HAS INVESTED since its arrival €7.5M, 53% OF THE €14M COMMITTED TO THIS DIVISION.

- H12 thus becomes one of the most efficient ferrosilicon furnaces in the world.ÁEurope's most competitive ferrosilicon furnaces.

Xallas Electricidad y Aleaciones, XEAL, has begun commissioning of the 12th ferrosilicon furnace in Cee after making an investment of two million euros. It is therefore operating with four of its five furnaces at full load, taking advantage of a profitable demand opportunity currently offered by the market.

Furnace 12 was taken offline at the end of November to undertake a major overhaul to modernize and automate the casting area. Key aspects of the renovation work include the incorporation of automatic equipment for opening and sealing the casting nozzles, autonomous cupola carriages that can be operated remotely using remote controls, a new 25-ton overhead crane for handling and pouring the cupolas containing the liquid alloy, and the redesign and expansion of the diffuse fume collection systems for the process.

This reform focuses on the 4 strategic axes of the company: improving occupational safety; compliance with environmental regulations, long-term care and maintenance of assets; and improved efficiency and productivity. Regarding the latter, the new equipment will increase competitiveness and make kiln 12 in Cee XEAL's most competitive kiln and one of the most competitive in Europe.

You may be interested in

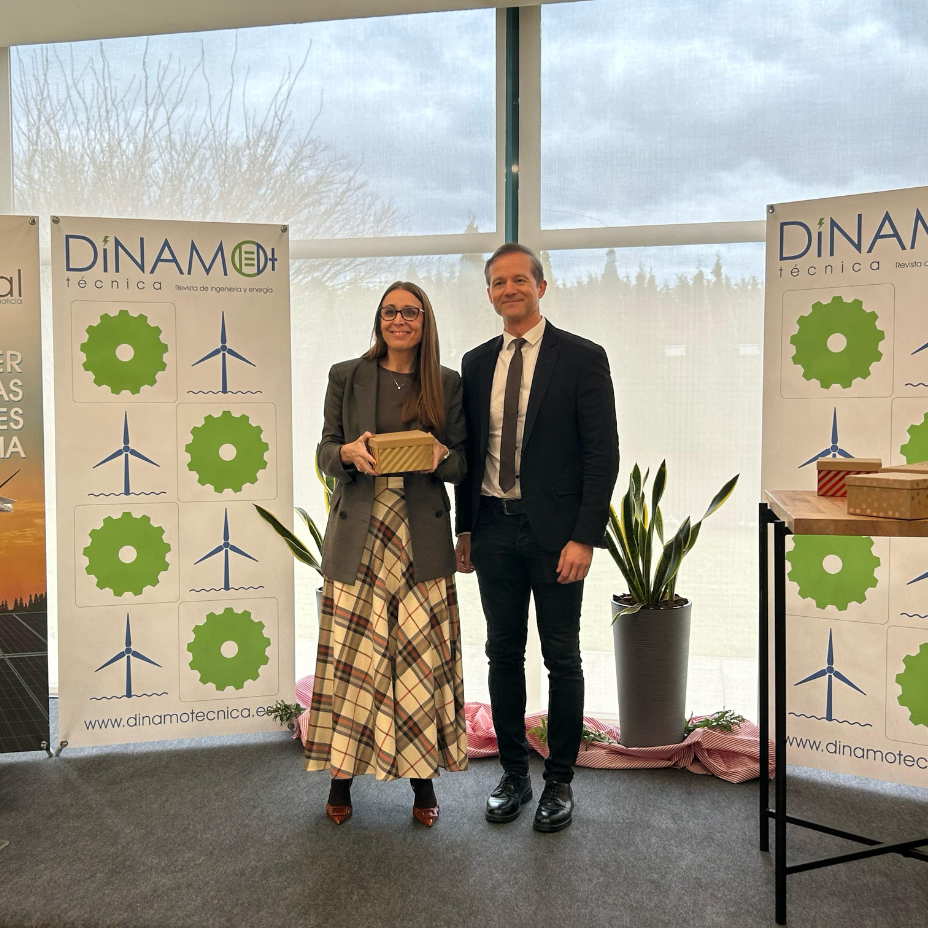

Cluergal premia la trayectoria de María Couto, CEO de XEAL, y su apuesta por las energías renovables

Cee, 14 de febrero de 2025_ El Clúster de Energías Renovables de Galicia (Cluergal) ha premiado esta mañana a María Couto, CEO de XEAL, como reconocimiento a su contribución al desarrollo de fuentes de energía renovables en la Comunidad de Galicia. Lo ha hecho en el marco de los IV Premios Enerxéticos que organizan. Bajo su dirección, XEAL […]

Cee, 22 de enero de 2025.- XEAL acaba de poner en funcionamiento un nuevo sistema de aspiración y filtrado de gases de los hornos 21 y 22 de la fábrica de Dumbría tras unos trabajos de construcción, instalación y puesta en marcha que han durado más de un año y en los que la compañía ha invertido 2,9 M€. El […]

Cee, December 23. XEAL celebrated with great success the Christmas Party with which closed the events commemorating the 120th anniversary of the company and the 30th anniversary of Energo-Pro. The party, which was held in the Auditorium of Vimianzo last Friday, was in charge of the prestigious company of Pablo Méndez [...]